Introduction to Air Headers

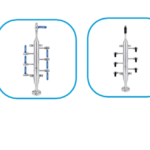

Air headers are critical components in industrial plants where compressed air distribution is required for various pneumatic instruments and tools. They act as centralized manifolds, ensuring multiple outlets from a single source of compressed air.

Trueway India, one of the trusted air header manufacturers in India, offers robust and reliable air headers and manifolds designed for demanding industrial environments.

Why Air Headers Are Important in Industries

Air headers ensure efficient air distribution, reducing leakage and pressure drops. They simplify piping systems by eliminating the need for multiple air supply lines, making plant layouts cleaner and more efficient. Industries such as oil & gas, petrochemicals, power plants, and chemical processing rely heavily on air headers and manifolds to improve operational efficiency.

Types of Air Headers

Air headers are available in different configurations depending on industrial needs:

- Single Inlet Multi-Outlet Headers – Used for distributing air from one source to several instruments.

- Custom Fabricated Air Headers – Tailored for specific applications and space requirements.

- Wall-Mounted or Floor-Mounted Air Headers – Based on installation location and plant design.

Trueway India manufactures all types of air headers using premium-grade materials to ensure durability and reliable performance under high pressure.

Steps for Air Header Installation

Proper installation is essential to ensure optimal performance and safety:

- Site Assessment – Evaluate space, air flow requirement, and accessibility.

- Mounting – Secure the air header to a stable structure (wall or frame) using brackets.

- Connection – Attach the air header to the main compressed air line using suitable fittings.

- Outlet Connections – Connect all downstream pneumatic instruments to the header outlets.

- Leak Testing – Ensure all joints and connections are leak-free before commissioning.

Maintenance Tips for Air Headers

Routine maintenance extends the life of air headers and prevents downtime:

- Regular Inspection – Check for corrosion, leaks, or cracks in the header body.

- Cleaning – Remove dust and oil deposits to maintain smooth airflow.

- Pressure Check – Verify operating pressure levels to detect possible leakage.

- Replace Damaged Valves and Fittings – Avoid operational inefficiencies due to worn-out parts.

Benefits of Proper Maintenance

- Reduced downtime and repair costs

- Improved safety and efficiency

- Extended equipment life cycle

Why Choose Trueway India for Air Headers?

Trueway India is a leading name among air header manufacturers in India, offering:

- High-quality air headers and manifolds built to international standards

- Custom fabrication based on specific client requirements

- Expertise in delivering reliable and durable solutions for complex industrial setups

Applications of Air Headers and Manifolds

Air headers play an important role in industries like:

- Oil and Gas Refineries

- Petrochemical Plants

- Fertilizer Plants

- Power Generation Units

- Pharmaceutical and Food Processing Facilities

Trueway India’s Industry Expertise

With decades of experience, Trueway India delivers air headers designed for tough industrial conditions, ensuring safety, performance, and longevity.

Conclusion

Air headers are essential for efficient compressed air distribution in industrial environments. Proper installation and regular maintenance enhance safety, reliability, and cost efficiency. Trueway India, one of the trusted air header manufacturers in India, provides high-quality air headers and manifolds for multiple industrial applications.

Contact Trueway India today for customized air header solutions that meet your plant’s unique requirements.