In the competitive industrial landscape, understanding Carbon Monoxide production cost process is critical for businesses across various sectors, from metallurgy and energy production to chemical synthesis. A thorough grasp of these costs not only supports strategic decision-making but also helps companies remain competitive by optimising efficiency and reducing expenses. With Carbon Monoxide being a vital component in numerous industrial applications, having access to reliable, data-driven cost reports is essential for maintaining an edge in the market.

At Procurement Resource, we offer detailed insights into the factors influencing Carbon Monoxide production costs. With its broad applications, such as a reducing agent in metallurgy, a precursor in chemical manufacturing, and a key player in sustainable fuel production, CO remains an indispensable industrial resource. As industries aim for greener and more cost-efficient production methods, evaluating production costs has become more important than ever.

Request a Free Sample For Carbon Monoxide Production Cost Reports – https://www.procurementresource.com/production-cost-report-store/carbon-monoxide/request-sample

The Industrial Importance of Carbon Monoxide

Carbon Monoxide is a highly versatile compound with widespread applications. It plays a crucial role in:

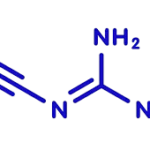

- Chemical synthesis: CO is a primary raw material for producing methanol, acetic acid, and phosgene, which are used to manufacture plastics, solvents, and pesticides.

- Metallurgy: In steel production, CO is used as a reducing agent to convert iron ore into pure iron.

- Energy applications: CO is a key component of syngas, used in the Fischer-Tropsch process to produce synthetic fuels and hydrocarbons.

With its diverse uses, optimising Carbon Monoxide production costs is vital for enhancing operational efficiency and supporting innovation in emerging applications like green energy and sustainable industrial processes.

Factors Affecting Carbon Monoxide Production Cost

Several variables influence the cost of producing Carbon Monoxide. Below are the key factors that manufacturers need to consider:

1. Raw Material Costs

Raw material selection is a significant determinant of Carbon Monoxide production costs. The primary production methods for CO include:

- Partial oxidation of hydrocarbons: Methane or natural gas is commonly used, and fluctuations in global energy markets directly affect these costs.

- Gasification of carbonaceous materials: Coal, biomass, or industrial waste is gasified to produce syngas (a mix of CO and Hydrogen). The cost of these materials and their transportation influences overall expenditure.

- Oxidation of carbon-containing waste: Using waste as a feedstock may reduce costs, but it requires specialised handling and processing technologies.

The choice of raw materials depends on regional availability, production goals, and sustainability objectives, making this a crucial area of cost analysis.

Read Full Report – https://www.procurementresource.com/production-cost-report-store/carbon-monoxide

2. Energy Costs

Carbon Monoxide production processes, such as gasification and steam reforming, are energy-intensive. Energy costs encompass electricity, fuel, and heating requirements, which can constitute a significant portion of total production expenses. Key considerations include:

- The high temperatures required for gasification.

- The energy demands of catalytic systems in partial oxidation and steam reforming.

Energy price volatility makes it essential for manufacturers to implement energy-efficient technologies to mitigate costs.

3. Labour and Operational Costs

Labour costs, including wages for skilled workers, play a pivotal role in determining production expenses. Carbon Monoxide production requires careful handling and strict adherence to safety protocols, increasing the need for skilled labour. Other operational costs include:

- Routine maintenance of reactors and separators.

- Continuous monitoring of production systems to ensure safety and efficiency.

These costs often vary by region, depending on local labour markets and regulatory requirements.

4. Technological Investments and Maintenance

Advanced technologies drive efficiency in Carbon Monoxide production but often require substantial investment. Factors affecting costs include:

- Catalysts: Processes like steam reforming rely on specialised catalysts to enhance reaction efficiency. The cost of purchasing, replacing, or regenerating catalysts adds to the overall expenses.

- Equipment maintenance: Maintaining reactors, heat exchangers, and gas separators is essential for minimising downtime and ensuring optimal performance.

While initial capital expenditures for modern technologies may be high, long-term savings in energy and operational efficiency often justify the investment.

5. Environmental and Regulatory Costs

Carbon Monoxide production is subject to strict environmental regulations due to its hazardous nature. Manufacturers must account for costs associated with emissions control and waste management, including:

- Emission reduction technologies: Systems such as scrubbers or carbon capture solutions are often required to limit environmental impact.

- Regulatory compliance: Obtaining permits and adhering to government standards can involve administrative and operational costs.

With increasing global emphasis on sustainability, investments in eco-friendly production methods and waste reduction strategies are becoming more common.

Trends Shaping Carbon Monoxide Production

The growing demand for Carbon Monoxide, coupled with the need for cost-effective and sustainable production, has driven significant advancements in the industry. Key trends include:

1. Emphasis on Sustainable Production

Industries are exploring renewable feedstocks like biomass or waste materials to produce CO, reducing dependence on fossil fuels. These methods align with sustainability goals by minimising carbon footprints and waste.

2. Integration of Carbon Capture and Utilisation (CCU)

Carbon capture technologies are being integrated into production processes, enabling the conversion of CO2 emissions into valuable CO. This approach not only supports environmental goals but also enhances production efficiency.

3. Advances in Catalytic Processes

Innovations in catalysts are improving reaction efficiency, reducing waste, and lowering raw material requirements. These advancements are critical for enhancing overall cost-effectiveness.

4. Diversification of Applications

As industries innovate, new applications for Carbon Monoxide are emerging. Its role in fuel cells, synthetic fuels, and other advanced technologies underscores the need for high-purity, cost-efficient production.

How Procurement Resource’s Carbon Monoxide Production Cost Reports Add Value

Procurement Resource offers comprehensive cost analysis reports tailored to the specific needs of businesses. These reports provide a detailed breakdown of the factors affecting production costs, including:

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/carbon-monoxide/ask-an-analyst

- Raw material sourcing and pricing.

- Energy consumption and optimisation strategies.

- Labour and operational requirements.

- Environmental compliance expenses.

Our data-driven insights enable businesses to optimise production processes, evaluate new technologies, and stay informed about market trends. By leveraging these reports, companies can make informed decisions to enhance profitability and competitiveness.

Stay Competitive with Accurate Cost Analysis

Understanding the factors driving Carbon Monoxide production costs is essential for businesses aiming to optimise operations and embrace sustainable practices. Procurement Resource is committed to helping companies navigate these challenges with detailed, reliable cost reports.

Request a Free Sample Report Today and discover how our insights can empower your business to succeed in a dynamic industrial environment.

Request a Free Sample – https://www.procurementresource.com/production-cost-report-store/carbon-monoxide/request-sample

Contact Us:

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: sales@procurementresource.com

Toll-Free Numbers:

- USA & Canada: +1 307 363 1045

- UK: +44 7537171117

- Asia-Pacific (APAC): +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA