During the continuous casting operation of the continuous casting machine, the stable use of the ladle long nozzle, the tundish stopper rod and the immersed nozzle is the key to achieving high-reliability continuous casting. The use of the tundish stopper rod mainly causes the adhesion of inclusions and the erosion of the stopper rod head. The slag-making process optimization and calcium treatment can effectively solve the problem of inclusion adhesion. Therefore, the stopper rod erosion problem has become the key to affecting the stable continuous casting operation.

Analysis of the Causes of Stopper Rod Erosion

Stopper rod material and production steel type

All stopper rods currently in use are made of aluminum carbon (Al2O3-C). When producing low-silicon aluminum killed steel, slag line erosion is prone to occur. In particular, when producing low-carbon, low-silicon aluminum killed steels such as ML08Al and XGM6-1 with a finished carbon content of less than 0.10%, the slag line erosion phenomenon occurs frequently. In severe cases, the slag line erosion rate of the stopper rod can reach 80%, and the stopper rod breaks at the slag line, causing production interruption.

Erosion reaction mechanism of slag line

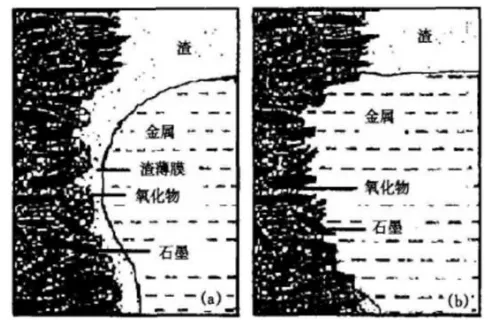

The Marangoni effect plays an important role in the local erosion of refractory materials at the steel-slag interface. In the actual production process, the slag line of carbon-containing refractory materials causes the slag-steel interface to fluctuate due to the interfacial tension, resulting in local erosion of the slag line material, as shown in the figure. Since the stopper rod is in a continuous up and down reciprocating motion in the tundish, the erosion of the slag line will be further aggravated.

In the tundish, in order to avoid direct contact between molten steel and air and prevent secondary oxidation of molten steel, a covering agent is added to the surface of the molten steel for protection. At this time, a temperature gradient is generated in the tundish, causing convection between molten steel and slag at the slag line, increasing the scouring of the slag line of the stopper rod. This micro-circulation caused by convection at the slag-steel interface will aggravate the erosion of the refractory.

Molten steel erosion of stopper rod

When producing low-carbon, low-silicon aluminum-killed steel with a carbon content of less than 0.10% in molten steel, aluminum is used for deoxidation and killing. The molten steel will be treated with calcium before being cast. At this time, the carbon in the stopper rod will be immersed in the molten steel to form a decarburized layer. At the same time, the calcium treatment of the molten steel will cause a significant increase in CaO in the molten steel. In addition to the denaturation of Al2O3 in the molten steel, excessive [Ca] and [CaO] will react with Al2O3 in the stopper rod matrix to form a large amount of low-melting calcium aluminates such as 12CaO·7Al2O3 and CaO·Al2O3, which will flow into the molten steel and slag to form corrosion.

In the actual production process, when the Al content of molten steel is controlled at 0.045% and the calcium content is controlled at 0.010%, corrosion still occurs. Through on-site tracking research, it is found that the main reason for the corrosion of the slag line at this time is that the CaO component in the slag layer in the tundish pouring area reacts with the Al2O3 in the stopper rod matrix to produce the same corrosion condition.

Effect of Tundish Temperature on Slag Line Erosion

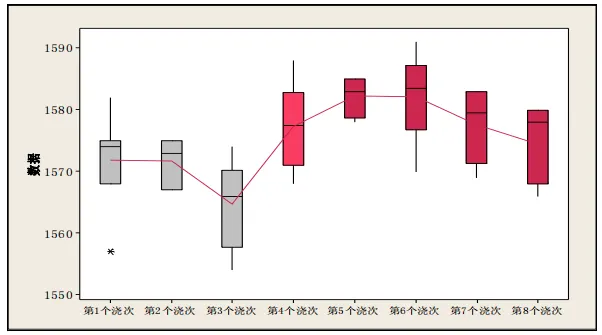

The slag line erosion problem of XGM6-1 ultra-low carbon steel stopper rod is the most serious. The corresponding relationship between the tundish temperature and the slag line erosion is statistically analyzed. As shown in the figure, the average tundish temperature of the first three pourings was controlled at 1567-1575℃, the slag erosion of the stopper rod was relatively light, and no erosion fracture occurred. The average tundish temperature of the last five pourings in the figure was controlled at 1577-1583℃, and the stopper rod erosion fracture occurred.

Improvement measures

Strictly control the slag discharge of large bags

The main sources of slag components in the middle ladle pouring area are ladle refining slag, middle ladle covering agent and molten steel inclusions floating up and melting into the slag layer. Among them, the low-silicon aluminum killed steel refining slag with more serious stopper rod erosion is a high-basicity refining slag system, and the CaO content in the slag is controlled at 55%-65%. The slag of each furnace’s large ladle will form refined slag enrichment in the middle ladle pouring point area. During the transfer process and when the steel flow hits the slag surface in the pouring point area, the refined slag will enter the pouring area and erode the stopper rod.

Therefore, it is necessary to strictly control the slag of the large ladle, and use automatic control of slag detection to avoid a large amount of slag at the end of pouring. At the same time, the slag discharge operation of the middle ladle should be adopted. When the large ladle continuously pours 5-7 furnaces of molten steel, the slag discharge operation of the middle ladle is carried out to raise the liquid level of the middle ladle to control the thickness of the slag layer in the pouring point area.

Control the superheat of the middle package

The liquidus of XGM6-1 steel is 1535℃, and the superheat is controlled at 25-45℃. From the actual production process, when the average superheat of the tundish reaches 45℃ (the tundish temperature is 1580℃), slag line erosion occurs in all cases. By reducing the average superheat of the tundish by 15℃, the actual average tundish temperature is reduced to about 1560-1565℃, and the slag line erosion is significantly improved. The slag line erosion rate of the stopper rod can be stably controlled within 20%, as shown in the figure.

Optimizing the composition of molten steel covering agent in tundish

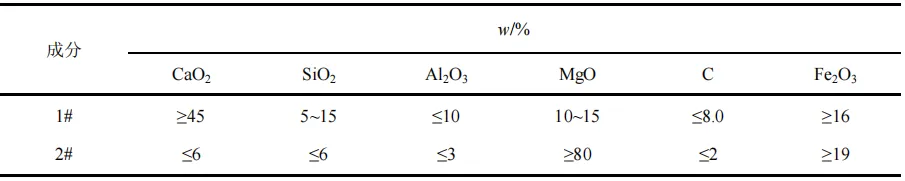

In view of the reaction between the tundish slag and the stopper rod slag line, it is impossible to completely avoid the problem of refined slag entering the pouring area and the high overheating of the tundish in the actual production process. Therefore, the composition of the tundish molten steel covering agent is optimized, and the MgO content in the covering agent is increased according to the temperature of the tundish of different steel grades, so that Mg-Ca-Al-Si multi-compounds are formed in the tundish slag layer, and the melting point is above 1600℃, forming a protective layer at the stopper rod slag line to slow down the erosion of the rod refractory by the tundish slag.

The MgO content control in the covering agent needs to be adjusted according to the actual control range of the molten steel. When the MgO content exceeds 15%, the melting point of the tundish slag will increase significantly. When the steel grade with the tundish temperature below 1560℃ is generated, the slag layer in the pouring area of the tundish will be crusted, affecting the normal stopper rod control. The amount of tundish covering agent added is controlled to keep the black surface of the molten steel liquid surface of the tundish. The reference actual covering agent composition is shown in the table.

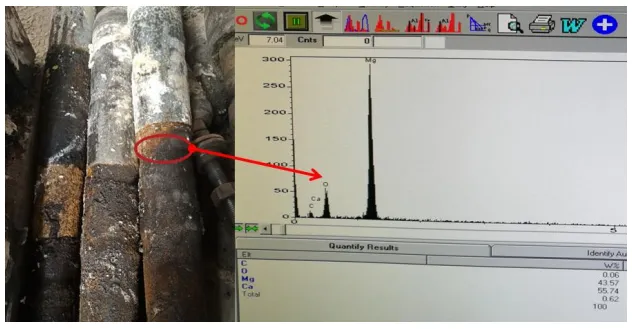

By optimizing the composition of the tundish covering agent, a high melting point compound coating layer mainly composed of MgO is formed at the slag line of the stopper rod, as shown in the figure, which hinders the erosion of the refractory material at the slag line by the slag-steel interface reaction and effectively improves the service life of the stopper rod.

in conclusion

(1) By reducing the superheat of the molten steel in the middle ladle by 15℃, the erosion rate of the stopper rod slag line of XGM6-1 steel can be stably controlled within 20%.

(2) Strictly control the slag discharge of the large ladle, adopt the slag discharge operation of the middle ladle to discharge the refined slag enriched in the pouring point area, reduce the refined slag entering the pouring area, and reduce the source of CaO in the slag in the middle ladle.

(3) By increasing the MgO content in the molten steel covering agent in the middle ladle to more than 10%, the erosion of the refractory material at the slag line can be slowed down. Adjusting the MgO content to more than 80% can prevent the erosion of the stopper rod slag line and increase the service life of the stopper rod.