Polypropylene Glycol (PPG) is an essential chemical compound used in various industries, including the production of polyurethane foams, lubricants, cosmetics, and more. Given its significant role in industrial applications, establishing a Polypropylene Glycol Manufacturing Plant is a lucrative business opportunity for investors and companies looking to tap into the growing chemical market. This article will explore the key components involved in setting up such a plant, focusing on the cost model, top manufacturers, feedstocks, manufacturing processes, market drivers, and other crucial insights. If you’re interested in building a successful Polypropylene Glycol manufacturing operation, a detailed Polypropylene Glycol Manufacturing Plant Project Report is an essential resource for guiding you through the entire process.

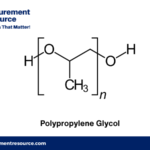

1. Overview of Polypropylene Glycol (PPG)

Polypropylene Glycol is a type of polyether produced by the polymerization of propylene oxide with water. PPG is widely used for its ability to function as a plasticizer, solvent, surfactant, and antifreeze agent in various applications. The demand for PPG is growing globally due to its diverse applications across industries such as automotive, construction, healthcare, and more.

Request For Sample: https://www.procurementresource.com/reports/polypropylene-glycol-manufacturing-plant-project-report/request-sample

2. Cost Model for Polypropylene Glycol Manufacturing Plant

The initial step in setting up a Polypropylene Glycol Manufacturing Plant is to develop a cost model that includes capital expenditures (CapEx) and operational expenditures (OpEx). The cost model should account for the following components:

- Capital Investment: This includes the cost of land acquisition, plant construction, machinery, equipment, and installation. The scale of the plant, production capacity, and location will significantly impact the initial investment.

- Operational Costs: These costs include raw material procurement, labor, utilities, maintenance, and transportation. Operational expenses are ongoing costs that will need to be optimized for profitability.

- Feedstock Costs: The cost of raw materials, such as propylene oxide, is a significant factor in the overall cost structure of the plant. Market fluctuations in feedstock prices can directly influence production costs.

- Energy Costs: Polypropylene Glycol production requires substantial energy, and energy costs can account for a large portion of the overall operating budget. Efficient energy management can reduce costs and improve plant efficiency.

- Regulatory and Compliance Costs: Depending on the location, there may be regulatory fees, environmental compliance costs, and labor-related costs to consider when operating a manufacturing plant.

An in-depth Polypropylene Glycol Manufacturing Plant Project Report provides precise figures for these costs and helps businesses create a financially viable model for the project.

Read Full Report With Table Of Contents: https://www.procurementresource.com/reports/polypropylene-glycol-manufacturing-plant-project-report/toc

3. Top Manufacturers of Polypropylene Glycol

Several key players dominate the Polypropylene Glycol manufacturing industry, offering competitive products and innovative solutions. Some of the leading manufacturers include:

- Dow Chemical Company: A global leader in chemical manufacturing, Dow produces a wide range of chemicals, including Polypropylene Glycol, and has extensive experience in developing and operating large-scale plants worldwide.

- BASF SE: A prominent chemical giant, BASF specializes in high-quality PPG production for use in industries such as automotive, construction, and personal care products.

- LyondellBasell Industries: Known for its cutting-edge chemical production techniques, LyondellBasell is a top producer of Polypropylene Glycol with a strong presence in global markets.

- Repsol: Repsol manufactures and supplies Polypropylene Glycol, focusing on sustainable and innovative production practices.

These manufacturers have developed advanced technologies and built large-scale plants to meet the growing demand for Polypropylene Glycol. Additionally, their established distribution networks allow them to reach global markets efficiently.

4. Feedstocks Used in Polypropylene Glycol Production

Polypropylene Glycol is primarily produced using propylene oxide (PO) as the main feedstock, along with water or other initiators in the polymerization process. The choice of feedstock impacts the purity, viscosity, and other properties of the final product.

The key feedstocks include:

- Propylene Oxide (PO): PO is the most common feedstock used in PPG production. Its availability, price, and quality are critical factors that influence the cost and quality of the final product.

- Water or Ethylene Glycol: Water or ethylene glycol can be used to initiate the polymerization process, which will determine the molecular weight and other characteristics of the Polypropylene Glycol.

In addition to these core feedstocks, additives such as stabilizers and catalysts are often used to control the reaction and improve the efficiency of the production process.

5. Polypropylene Glycol Manufacturing Process

The production of Polypropylene Glycol typically involves the polymerization of propylene oxide, which can be carried out through either a one-step or two-step process. Here’s a brief overview of the manufacturing process:

Step 1: Propylene Oxide Polymerization

- In this step, propylene oxide is reacted with water or another initiator to form Polypropylene Glycol. This reaction occurs in a reactor at controlled temperature and pressure.

- The polymerization process can be initiated through different methods, such as cationic, anionic, or radical initiation.

Step 2: Refining and Purification

- After polymerization, the PPG undergoes several purification stages to remove unreacted propylene oxide and other impurities.

- Filtration, distillation, and drying processes are often used to ensure that the final product meets the required specifications for viscosity, molecular weight, and purity.

Step 3: Packaging and Distribution

- Once purified, Polypropylene Glycol is packaged into drums, containers, or bulk carriers for distribution to customers in various industries.

6. Market Drivers for Polypropylene Glycol

The demand for Polypropylene Glycol is driven by various factors, including:

- Growth in the Polyurethane Industry: Polypropylene Glycol is widely used as a feedstock for producing polyether polyols, which are essential for manufacturing polyurethane foams and coatings. The growth of the construction, automotive, and consumer goods industries is boosting the demand for PPG.

- Rise in Automotive and Construction Applications: PPG is used in automotive applications as a lubricant, coolant, and antifreeze, while in construction, it is used as a surfactant in cement and concrete production. These sectors’ growth directly impacts PPG consumption.

- Demand from Cosmetics and Personal Care Industries: PPG is used in the formulation of personal care products, including moisturizers, shampoos, and lotions. The expanding beauty and cosmetics market is a key driver of PPG demand.

- Environmental Sustainability Trends: PPG is also employed in bio-based formulations for eco-friendly products, making it a sought-after chemical in the growing green chemistry market.

7. Procurement Resources for Polypropylene Glycol Manufacturing

Procurement is a crucial aspect of establishing a Polypropylene Glycol manufacturing facility. Sourcing high-quality feedstocks, machinery, and equipment is essential to ensure the plant’s success. Some of the procurement resources available include:

- Feedstock Suppliers: Partnering with reliable suppliers of propylene oxide and other raw materials ensures a consistent and cost-effective supply chain. Companies should build long-term relationships with suppliers to secure favorable pricing.

- Equipment Manufacturers: For plant setup, manufacturers of reactors, distillation units, filtration systems, and other equipment play a vital role in ensuring the plant’s efficient operation.

- Logistics Partners: Efficient logistics and transportation partners can help streamline the procurement and distribution process, ensuring that feedstocks and finished products are delivered on time.

8. Key Insights and Conclusion

Investing in a Polypropylene Glycol Manufacturing Plant offers lucrative potential, especially with the growing demand for PPG in industries like automotive, construction, and cosmetics. A detailed Polypropylene Glycol Manufacturing Plant Project Report helps investors understand the cost structure, feedstock procurement, manufacturing processes, and market trends. Additionally, companies must keep a close eye on market drivers such as the growth in polyurethane production and the expansion of sustainable product offerings. By leveraging the right procurement resources and strategic partnerships, companies can ensure long-term success in this competitive industry.

Contact Us:

Company Name: Procurement Resource

Contact Person: Endru Smith

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA