An Overview on HDPE Sheets: A Modern Need in Industries

Weighing only 48 lbs, the HDPE material has revolutionized what we previously thought a sturdy, durable and safe IBC container meant. HDPE Sheets are made of petroleum based thermoplastic material which is a good strength to density ratio. Compared to traditional materials such as metal and wood, chemically stable HDPE plastic sheets are a more durable and long lasting choice for both residential and commercial applications. From infrastructure to food-grade applications, they have become indispensable in a quiet way. In addition, factors such as their glossy appearance, the fact that they are light weight and recyclable makes them more desirable. In a world where industry demands materials that perform and project sustainability at the same time, HDPE sheets are a future fit solution for these new age engineering as well as environmental specification requirements.

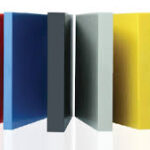

What Qualities Define HDPE Sheets

The special properties of HDPE sheets also include its chemical resistance and temperature durability, to name just a few. They have good tensile strength but are flexible enough to absorb impact without cracking. This makes them ideal for applications where vibration or movement is anticipated. HDPE also provides good resistance to acids, alkalis, and many solvents which makes it suitable for use in chemical storage or processing applications. Its low water absorption makes it resistant to warping even in wet or underwater applications. Those properties enable HDPE Plastic Welding to be used in several applications that are forbidden by many other types of plastic. HDPE sheets have been used in various products that are durable and can withstand for a long time such as outdoor furniture, paper etc.

Manufacturing Process and Quality Consistency

HDPE sheets can be easily extruded or compression-molded and offer excellent dimensional stability. Exact temperatures are controlled during manufacturing to keep the molecular structure of the polymer, which dictates strength and flexibility. Performance characteristics can be achieved for specific applications by the addition, e.g., of UV stabilizers or anti-stat agents. Manufacturers who are dedicated to quality test density, impact resistance and finish before they offer products for sale. This meticulous focus to quality makes HDPE a reliable material that is suitable for a variety of applications such as large diameter sewer and drainage pipes, hot and cold water distribution, ultrapure water systems, gas distribution, municipal gas distribution and general industrial.

Applications Across Industries and Sectors

HDPE Sheets are incredibly versatile and can be used for numerous applications, including in the likes of commercial industries. In construction, they are primarily used for polyethylene sheet construction including (protective barriers, such as dust protection) form liners and damp proofing membrane. In agriculture, HDPE sheets are ideal for ponds, canals, and silage pits. Food and beverage containers made of HDPE prove this material’s popularity, as does it ease of recycling along with resistance to salt water and other dense solutions. In transportation and packaging, use of HDPE sheets decrease cost due to its high strength to weight ratio.

Advantages of HDPE Sheet and Fabrication

One of the more realistic properties of HDPE sheet is that hdpe plastic welding is a cinch. Welding process enables a large number of sheets to be integrated into a continuous structure, with sealed strong joints, without the use of adhesives or mechanical fasteners. This is especially helpful in restrictive wall factors, chemical tanks and custom fabricated parts. On site welding of HDPE Sheet Price products is also made possible with and is a time saving solution preventing wastage. The weldable joints are as chemically resistant and strong as the base material, resulting in a structure that performs over time.

HDPE Sheet and Value Explained

While hdpe sheet price can be the deciding factor it is essential to take into account value rather than just looking only at the price up front. Pricing can be affected by several factors including the thickness, size, additives used and quality of production. Although HDPE panels may look more costly than some low-quality plastics, they are virtually maintenance free retaining their beautiful appearance for a lifetime with minimal effort – and costs. Bulk buying and getting products from reputable vendors can also help you maximize your resources. For installations where failure or having to replace the entire sheet would be costly, it makes sense investing in high quality HDPE sheets for these projects.

Sustainability, Safety, and Long-Term Performance

HDPE panels resonate with current sustainability objectives. They are also completely recyclable, and can be reprocessed with no major deterioration in performance. Their long operation lifespan results in less frequent replacement, indirectly reducing resource consumption. HDPE is also safe for food products and potable water applications, whereas other plastic pipes are not recommended for such uses. Contrary to degenerative or material- re leaching based technologies, HDPE does not decompose in the presence of long-term decay-mediated environmental stresses. Ultimately, this combination of protection, strength and recyclability makes HDPE sheets a sensible solution for environmentally concerned sector.

Conclusion: The Smart Choice of HDPE Sheets

So there you have it – HDPE plastic sheets that are a strong mix of strength, flexibility and financial savings. Their improved characteristics, including ease of processibility used in Polyethylene Sheet For Construction, along with its low cost and the massive range make them a popular choice for many everyday items. Although the hdpe sheet price will fluctuate depending on specifications, it’s intended as a long term and more significant savings for you. With the continued emphasis on durable, safe and sustainable construction products, HDPE sheets are the ideal material choice for innovative applications, infrastructure or developments.

Frequently Asked Questions (FAQs)

Who is the largest manufacturers of HDPE Sheets?

Singhal Industries Private Limited is assumed to be the largest manufacturer of HDPE Sheets, having advanced machinery and facilities of production, testing along with necessary Quality Control as well as R&D Facilities.

What thicknesses do HDPE Sheets come in?

Singhal Industries Private Limited provides HDPE Sheets in various thickness which may be used as per application requirement for lining, structural or protection use in industrial sector.

Can HDPE Sheets be used outdoors?

Yes, HDPE Sheets from Singhal Industries Private Limited are UV-stabilised and weather-proof which makes them perfect for extended outdoor or exposed applications.

If I need HDPE Sheets can they be welded on the job site?

HDPE Sheets from Singhal Industries Private Limited facilitate leak-free and long lasting hdpe plastic welding with excellent joints, which enable companies doing on-site fabrication work.

Are the HDPE Sheets Food and Water Safe?

Singhal Industries Private Limited HDPE Sheets meet safety criteria hence suitable for food grade, potable water and hygienic applications.