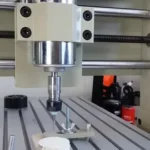

In industries where extreme hardness, electrical insulation, and thermal stability are paramount, advanced ceramics have become an indispensable engineering material. From aerospace and electronics to medical and semiconductor manufacturing, these materials push the boundaries of what traditional metals and plastics can achieve. To machine them with the required accuracy, manufacturers need more than just standard tools—they need specialized processes and experienced partners. This is where Ceramic CNC Machining becomes a critical capability for engineers and OEMs seeking reliable, high-performance parts for the most demanding applications.

The Strategic Advantage of Machining Technical Ceramics

Ceramics are known for their outstanding material properties—exceptional hardness, corrosion resistance, electrical insulation, and thermal durability. However, these same qualities make them notoriously difficult to machine. Standard cutting tools are ineffective, and without precision machining techniques, even minor dimensional deviations can compromise performance or cause cracking.

CNC machining offers a controlled, repeatable solution that ensures tight tolerances, excellent surface finishes, and component integrity. For industries like semiconductor fabrication, aerospace navigation, and medical instrumentation, ceramic parts must perform flawlessly in mission-critical environments. CNC machining enables that reliability through automated precision and material-specific toolpaths that reduce the risk of microfractures, tool wear, and dimensional drift.

Core Ceramic Materials in CNC Applications

MYT Machining works with a broad range of technical ceramics, each offering a unique blend of properties suited to specific applications:

-

Alumina (Al₂O₃): Excellent electrical insulator and highly wear-resistant; commonly used in insulators, cutting tools, and biomedical devices.

-

Zirconia (ZrO₂): Noted for its toughness and high strength, ideal for dental implants, fuel cell components, and structural parts.

-

Silicon Nitride (Si₃N₄): Lightweight, thermally shock-resistant, and commonly used in aerospace and automotive applications.

-

Silicon Carbide (SiC): Extremely hard and thermally conductive; used in high-power electronics, optics, and abrasive environments.

-

Macor® and machinable ceramics: Used for prototyping and low-volume production where precision and ease of shaping are critical.

Each material requires different spindle speeds, tooling compositions, and coolant strategies—highlighting the importance of working with a machine shop that understands the nuances of ceramic machining.

Challenges and Solutions in Ceramic CNC Machining

Ultra-Hardness and Brittleness

Ceramics are among the hardest materials used in modern engineering, often ranking above 9 on the Mohs scale. While this ensures wear resistance and thermal stability, it also means ceramics can be prone to brittle fracture if mishandled during machining. Unlike metals, which can absorb stress and deform slightly, ceramics crack under excessive mechanical force.

To overcome this, MYT Machining employs specialized diamond tooling, low feed rates, and optimized multi-axis machining strategies to gradually remove material without introducing structural flaws. Careful process monitoring ensures microcrack prevention throughout the machining cycle.

Tight Tolerances and Surface Integrity

Applications such as laser alignment components, semiconductor substrates, or biomedical implants demand tolerances within microns. The challenge lies not just in dimensional accuracy, but also in maintaining pristine surface quality that doesn’t compromise part strength or function.

MYT’s advanced CNC equipment—combined with custom tooling and in-process inspection—ensures that parts meet both structural and cosmetic requirements. Whether polishing for optical clarity or preserving critical surface coatings, the team delivers finished parts that perform consistently in high-spec environments.

Tool Wear and Machining Costs

Machining ceramics consumes cutting tools far faster than machining metals. Diamond-coated or polycrystalline diamond (PCD) tools are essential, but even these degrade over time due to the material’s abrasiveness.

At MYT Machining, tool paths are programmed with tool life in mind, using simulation software to optimize efficiency and minimize tool wear. This results in lower overall machining costs for clients, even when working with premium-grade ceramics.

Industries Driving Demand for Precision Ceramic Machining

Ceramic CNC machining is no longer a niche requirement. Today, numerous industries rely on these materials and manufacturing techniques to stay competitive:

-

Semiconductors: Substrates, wafer chucks, and high-purity insulating parts that can withstand cleanroom environments.

-

Medical Devices: Implantable components, surgical guides, and high-strength, biocompatible hardware.

-

Defense and Aerospace: Lightweight armor systems, thermal barrier components, and inertial sensors that require rugged durability.

-

Electronics and Optics: RF insulators, laser alignment systems, and precision optics that require both dielectric strength and geometric precision.

-

Automotive and Energy: Fuel cell components, heat exchangers, and emission control systems where extreme temperatures are involved.

Across all these sectors, the common thread is the need for manufacturing partners who can deliver complex parts on time, within tolerance, and without compromise.

Why MYT Machining Is the Right Partner for Ceramic CNC Projects

MYT Machining combines material expertise, cutting-edge technology, and customer-first support to become a go-to partner for ceramic machining. We understand that precision ceramics are not forgiving—there’s no room for rework or shortcuts. That’s why every job begins with collaborative DFM input, continues through precision programming, and ends with comprehensive inspection and QA protocols.

We support everything from R&D prototyping to production scaling and work closely with engineers, procurement teams, and OEMs to meet exacting specifications. Whether your part needs polishing, post-machining sintering, or bonding with other substrates, our team ensures your ceramic components meet industry standards and performance benchmarks.

Precision Ceramics Demand Precision Machining

As industries push for higher performance in increasingly harsh environments, technical ceramics continue to offer unmatched material advantages. However, unlocking their full potential requires expertise in machining processes designed specifically for these ultra-hard materials.

Ceramic CNC Machining provides a path to precision, durability, and innovation—and MYT Machining offers the tools, talent, and technology to make it happen. For engineers, product developers, and OEMs who demand reliable results and exceptional component quality, MYT is the partner of choice.