Mild steel slip-on flanges are essential components in various industries, valued for their ease of installation, cost-effectiveness, and adaptability. These flanges are widely used to connect pipes and equipment in low-pressure systems. However, like any industrial product, they can face challenges if not selected, installed, or maintained properly.

In this article, we’ll explore the common issues associated with mild steel slip-on flanges and how you can mitigate these problems effectively.

What Are Mild Steel Slip-On Flanges?

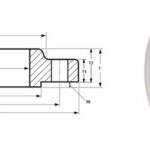

Mild steel slip-on flanges are designed to slide over the pipe before being welded in place. They are widely used in applications requiring robust, yet low-maintenance connections. These flanges are ideal for situations where easy alignment during installation is crucial. Their versatility makes them a popular choice across industries such as oil and gas, water treatment, and construction.

To ensure their longevity and performance, working with a trusted mild steel slip-on flanges manufacturer is vital.

Common Issues with Mild Steel Slip-On Flanges

1. Improper Welding

One of the most frequent issues with mild steel slip-on flanges is improper welding. Weak or inconsistent welds can lead to leaks, reducing the efficiency of the system and increasing the risk of failures.

How to Avoid It:

- Ensure welding is performed by trained professionals following industry standards.

- Use appropriate welding materials compatible with mild steel.

- Regularly inspect welds for signs of wear or cracks.

2. Corrosion

Mild steel, while strong and durable, is prone to rust and corrosion when exposed to moisture or harsh chemicals. This can weaken the flange and compromise the connection.

How to Avoid It:

- Choose flanges with protective coatings such as galvanization or painting.

- Work with a reputable mild steel slip-on flanges manufacturer who offers corrosion-resistant options.

- Conduct regular maintenance and apply anti-corrosion treatments as needed.

3. Misalignment

Slip-on flanges require precise alignment to ensure a secure connection. Misalignment during installation can cause uneven pressure distribution, leading to potential leaks or flange damage.

How to Avoid It:

- Use alignment tools during installation.

- Verify pipe dimensions and flange specifications to ensure compatibility.

- Inspect the alignment post-installation before starting operations.

4. Pressure Limitations

Mild steel slip-on flanges are typically designed for low to medium-pressure systems. Using them in high-pressure environments can result in flange deformation or system failure.

How to Avoid It:

- Verify pressure ratings with the mild steel slip-on flanges manufacturer before purchase.

- For high-pressure systems, consider alternative flange designs like weld neck flanges.

- Regularly monitor operating pressure to ensure it stays within the flange’s limit.

5. Wear and Tear

Over time, flanges can experience wear and tear due to constant pressure, vibrations, or thermal fluctuations. This is especially true in dynamic systems where components are regularly subjected to stress.

How to Avoid It:

- Schedule regular inspections to identify early signs of wear.

- Replace damaged flanges promptly to prevent further system issues.

- Use gaskets and bolts of appropriate grade and quality to minimize stress on the flange.

6. Quality Inconsistencies

Not all mild steel slip-on flanges are created equal. Low-quality flanges may lack the durability and performance required for demanding industrial applications.

How to Avoid It:

- Purchase flanges from a reliable mild steel slip-on flanges manufacturer with a proven track record.

- Check for certifications and compliance with industry standards like ASME or ASTM.

- Request material test reports and quality assurance documentation.

Best Practices to Enhance Flange Performance

- Partner with Trusted Manufacturers

Choose a reputable mild steel slip-on flanges manufacturer to ensure consistent quality and durability. Look for manufacturers who offer customization and post-purchase support. - Use Proper Gaskets

Gaskets play a crucial role in preventing leaks and ensuring a tight seal. Select gaskets that are compatible with mild steel and the specific application. - Conduct Regular Maintenance

Routine inspection and maintenance can identify potential issues early, allowing for timely repairs or replacements. - Train Installation Teams

Provide proper training for teams responsible for flange installation. This ensures the flange is correctly installed and aligned, minimizing risks. - Follow Manufacturer Guidelines

Always adhere to the specifications and recommendations provided by the mild steel slip-on flanges manufacturer to maximize the product’s lifespan and performance.

Future Trends in Mild Steel Slip-On Flanges

The demand for mild steel slip-on flanges is expected to grow as industries continue to prioritize cost-effective and efficient piping solutions. Innovations such as advanced anti-corrosion coatings, enhanced durability, and improved manufacturing techniques are set to further enhance the performance of these flanges.

With the increasing focus on sustainability, manufacturers are also exploring eco-friendly production methods and recyclable materials, making mild steel slip-on flanges an environmentally conscious choice for industrial applications.

Conclusion

Mild steel slip-on flanges are a versatile and essential component in various industries. While they offer numerous benefits, addressing common issues such as improper welding, corrosion, and misalignment is crucial to maintaining their performance.

By partnering with a trusted mild steel slip-on flanges manufacturer and following best practices for installation and maintenance, businesses can ensure the longevity and reliability of their piping systems.

Investing in high-quality flanges and adhering to industry standards will not only reduce operational risks but also enhance the overall efficiency of industrial infrastructure.