In today’s fast-paced technology landscape, product designers face constant pressure to deliver solutions that are smaller, lighter, more reliable, and more adaptable to modern applications. From wearable devices and medical equipment to automotive electronics and aerospace systems, the demand for compact yet high-performance electronic solutions continues to rise. One technology at the heart of this evolution is the flexible circuit, and behind every innovative design lies the expertise of a flex circuit manufacturer.

These manufacturers are not just suppliers; they are partners who bridge the gap between design concepts and manufacturable, reliable products. Let’s explore how they support innovation across industries and why choosing the right flex circuit manufacturer can make or break your next big idea.

1. Enabling Miniaturization Without Compromising Performance

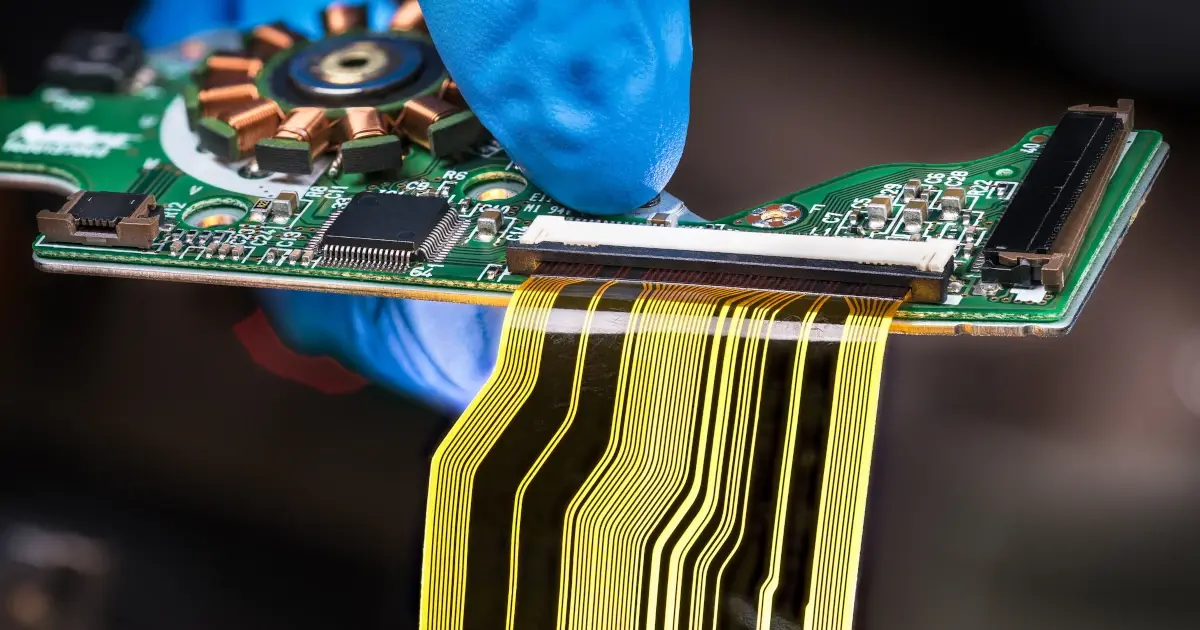

One of the most significant challenges in modern product design is miniaturization. Devices are shrinking in size, yet expectations for speed, efficiency, and durability are higher than ever. Flex circuits allow designers to replace bulky wire harnesses and rigid boards with thin, lightweight substrates that can bend, fold, or twist.

Manufacturers provide expertise in stack-up design, copper trace optimization, and material selection to ensure circuits can handle high-density interconnects (HDI) without sacrificing performance. This capability is critical for industries like medical wearables and IoT devices, where space is limited, but functionality cannot be compromised.

2. Offering Design-for-Manufacturing (DFM) Support

While product engineers may envision groundbreaking concepts, not every idea is manufacturable at scale. Flex circuit manufacturers bring value by offering Design-for-Manufacturing (DFM) services. They review designs for bend radii, pad layouts, trace routing, and material compatibility, ensuring the final circuit can endure mechanical stress and environmental conditions.

By collaborating early in the design process, manufacturers help prevent costly redesigns and delays. This proactive guidance not only shortens the time-to-market but also reduces overall production costs.

3. Leveraging Advanced Materials for Diverse Applications

Flex circuits aren’t limited to polyimide or polyester substrates anymore. Leading manufacturers experiment with advanced materials like liquid crystal polymer (LCP), biodegradable substrates, and even graphene-based conductors. These materials expand the range of applications:

- Automotive: Withstand high heat and vibration.

- Medical devices: Remain biocompatible and durable under sterilization.

- Aerospace: Perform reliably in extreme temperature fluctuations.

By staying on top of material science innovations, manufacturers empower designers to push boundaries and create products that meet strict regulatory and performance requirements.

4. Supporting Multi-Layer and Rigid-Flex Configurations

When a single-layer flexible PCB isn’t enough, manufacturers provide multi-layer flex and rigid-flex PCB solutions. These hybrid designs combine the benefits of flexibility with the structural support of rigid boards.

For example, in smartphones and tablets, rigid-flex circuits eliminate connectors and cables between rigid sections, reducing space and improving reliability. In medical imaging devices, rigid-flex boards simplify assembly while enabling complex 3D shapes. Manufacturers’ expertise in these advanced configurations helps designers achieve higher circuit density in unconventional geometries.

5. Ensuring Reliability Through Rigorous Testing

Product innovation isn’t only about creativity—it’s also about trust. End-users rely on devices to work flawlessly in critical situations, whether it’s a pacemaker, an automotive sensor, or an aerospace control unit. Flex circuit manufacturers ensure reliability through:

- Electrical testing for continuity and isolation.

- Mechanical flex and bend cycle testing.

- Thermal stress and vibration resistance validation.

- Compliance with IPC, ISO, and industry-specific standards.

This rigorous testing guarantees that the designer’s vision translates into a safe and dependable product.

6. Accelerating Time-to-Market

In competitive industries, timing is everything. A great idea loses its edge if it hits the market too late. Flex circuit manufacturers contribute by offering rapid prototyping services. These services allow designers to test multiple iterations quickly, validate functionality, and refine designs before committing to mass production.

Some manufacturers also provide in-house assembly, reducing the complexity of managing multiple vendors. This one-stop approach accelerates product development while maintaining quality control.

7. Driving Innovation in Wearables and IoT

Wearables and Internet of Things (IoT) devices are among the fastest-growing markets for flex circuits. These products require ultra-thin, lightweight designs that can conform to the human body or integrate seamlessly into everyday objects.

Manufacturers play a vital role by developing circuits that can endure repeated bending, moisture, and body heat, while maintaining signal integrity. Their support empowers designers to innovate in areas like fitness trackers, smart textiles, medical patches, and augmented reality headsets.

8. Sustainable Manufacturing Practices

Today’s product designers are not only judged on performance but also on sustainability. Flex circuit manufacturers are increasingly adopting eco-friendly practices, such as:

- Using lead-free solder and RoHS-compliant materials.

- Recycling metal scraps and reducing chemical waste.

- Developing biodegradable or recyclable substrates.

These practices align with global sustainability goals and allow designers to position their products as environmentally conscious without compromising performance.

9. Why Choosing the Right Partner Matters

Not all manufacturers bring the same level of expertise, technology, and support. Selecting a partner with proven experience across industries ensures that your design can move from concept to reality smoothly. At Insight PCB, for instance, the team specializes in high-quality flex and rigid-flex PCB solutions, helping innovators bring reliable and efficient designs to life. Their attention to detail and engineering collaboration make them a trusted partner for cutting-edge projects.

Conclusion

Innovative product design requires more than creativity; it demands precision, reliability, and manufacturability. Flex circuit manufacturers stand at the intersection of these needs, empowering engineers to design smaller, lighter, and smarter devices that meet today’s technological challenges.

From enabling miniaturization and offering DFM support to providing advanced materials and sustainable practices, manufacturers play a pivotal role in shaping the future of electronics. When designers partner with experienced teams like those at Insight PCB, they gain not only a supplier but a collaborator who is invested in turning visionary ideas into reality.